PRODUCT

FA506 Ring spinning machine

Category:

Ring frame machine

Keyword:Yarn Spinning machine line

DETAILS

Features

1.FA1506 Ring Spinning frame series are made from the leading design proposal, advance ed manufacturing methods and perfect special parts and components.They ensure high quality yarn spring.The machine features convenient operation and easy management due to its high automation.It is suitable for spinning of cotton and synthetic fibers or their blends to produce weaving or knitting yarns.

2.Exact headstock driving system is the foundation of producing high quality yarn.The headstock of FA1506is dc quipped with open auto-dropping lubrication and smoother driving.

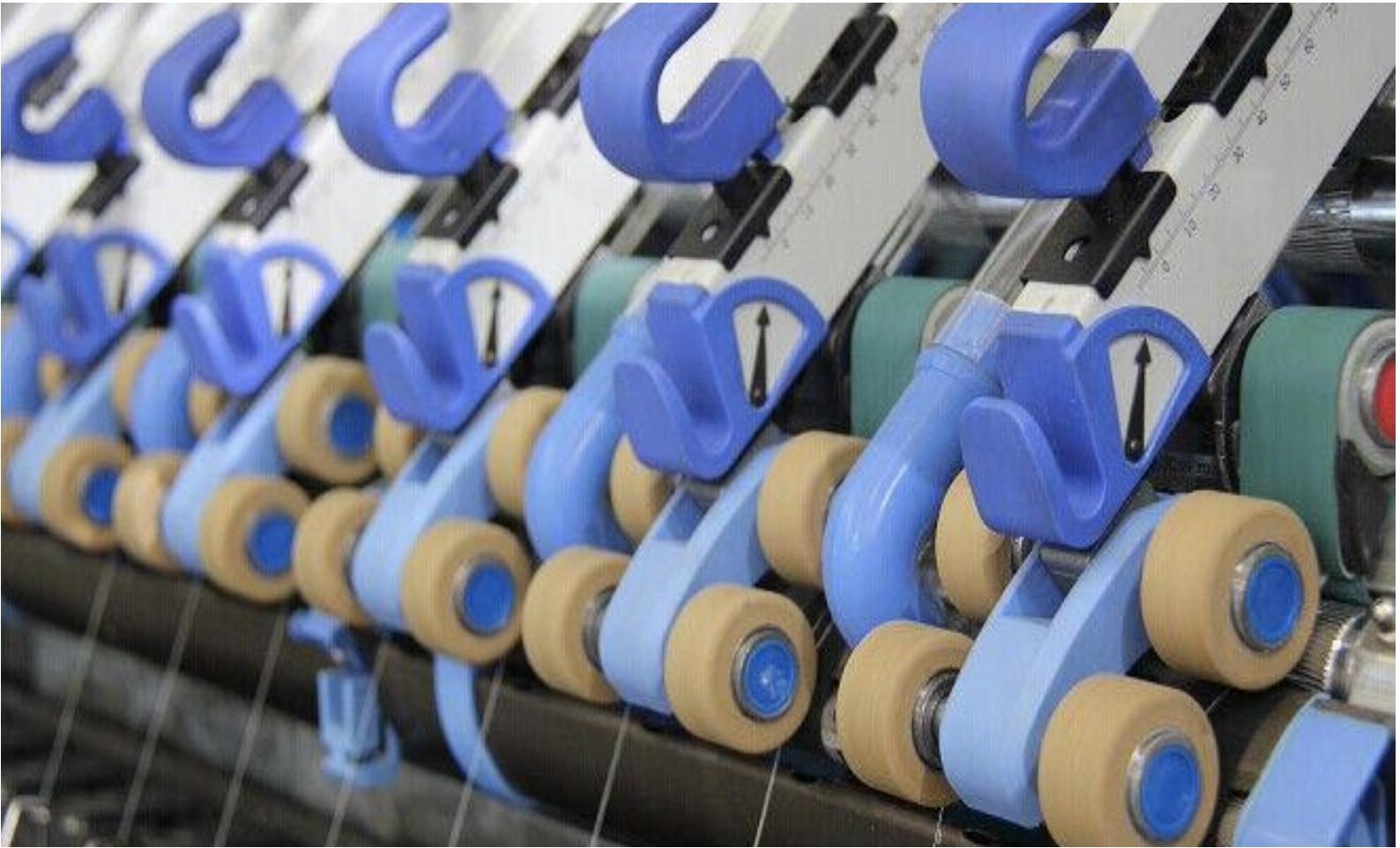

3.Adopt the CAPD technology ,optimize arrangement of middle frame, add up the spring pieces, ensure a better aseismic property and smooth running.

4.The machine adopts the high precision main shaft, and the driving is stable and reliable.

5.The maximum mechanical speed for spindle- is up to 25000rpm.

6.Optimize design for the air channel, improve the suction effect,ensure the least different air suction at high speed running.

7.For the building cam driving motion, using the precise worm box,eliminate the interim stopping,ensure without the coil slippage while winding-on high speed winder.

8. The roving creel is shaped by steel plate, makes perfect looking.

9.Equipped with traveling cleaner,core spandex yarn spinning device, slubby yarn spling device and roving traveling device.(Option)

10.Up - suction and under ground - suction are at customers(Option)

11.Equipped with top pulley made from ABS material.(Option)

Details

|

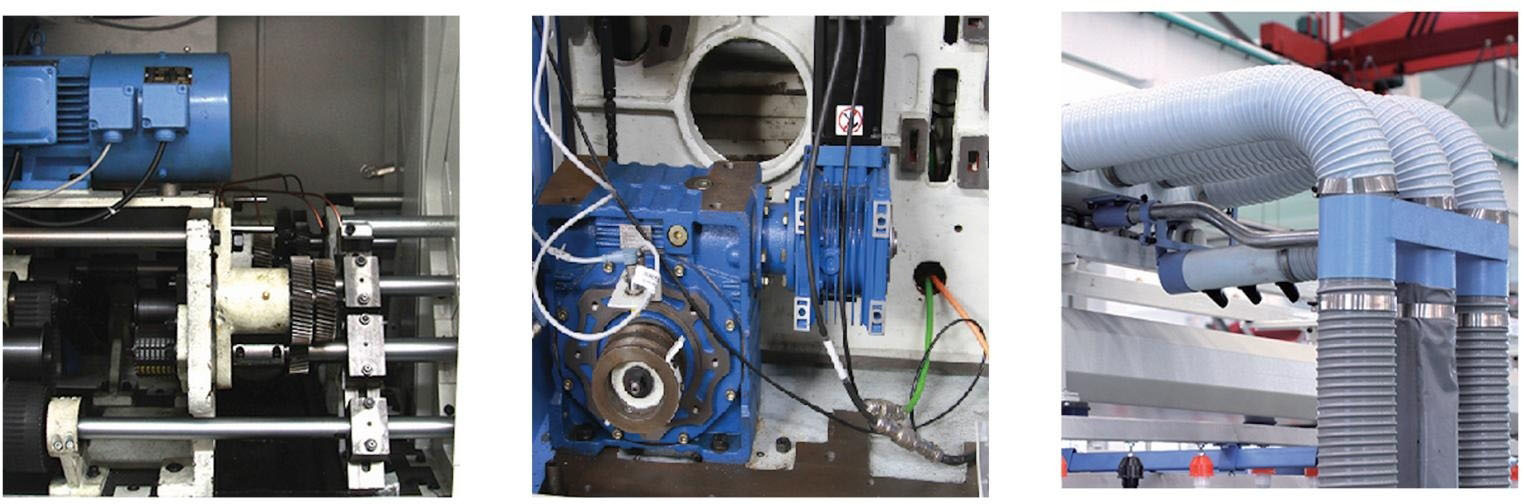

Headstock Transmission |

Winding System |

Blowing Suction Device |

|

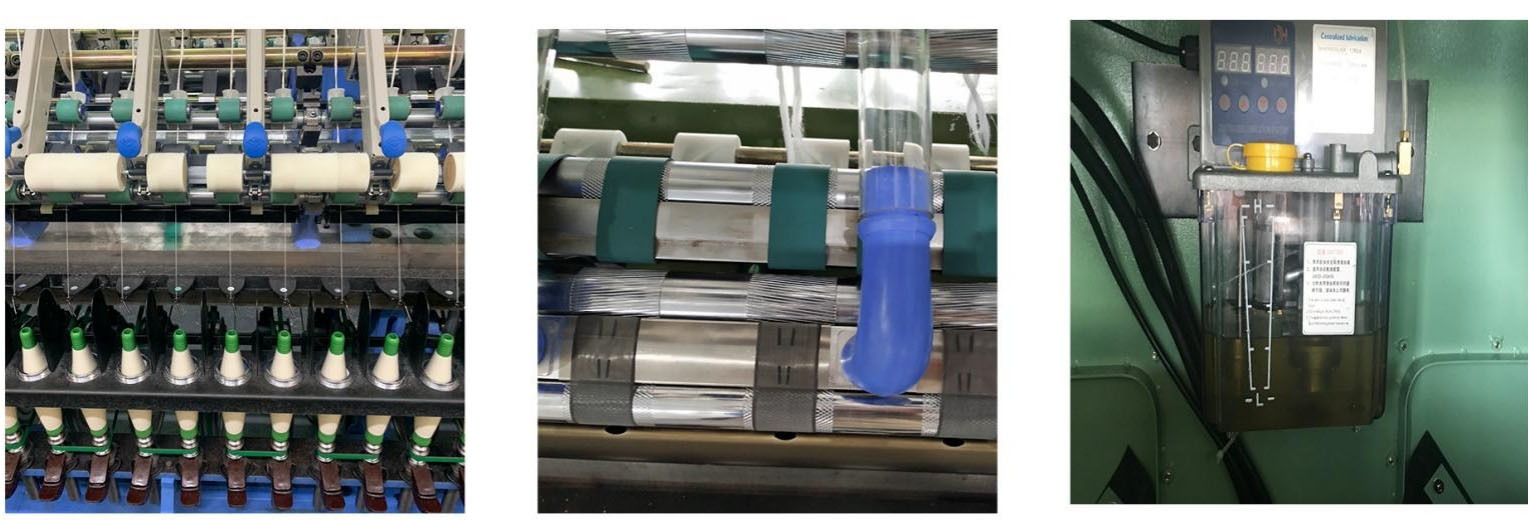

Drafting &Spindle transmission |

Roller without Mechanical Wave |

Lubrication System |

Specifications

|

Spindle Gauge |

70 mm |

|

No.of spindles |

From 96 up to 516 spindles with increment by 12 |

|

Lifting |

205,180mm (Bare blade type Spindle) |

|

Ring Diameter |

Φ35,Φ38,Φ40,Φ42,Φ45mm |

|

Yarn Count |

4.9-97.2tex(120-6Ne) |

|

Twisting |

230-1740 (T/m) |

|

Spindle Speed |

12000-25000 (rpm) |

|

Draft Ratio |

Total draft:10-50 |

|

Twist Direction |

Z or S |

|

Draft System |

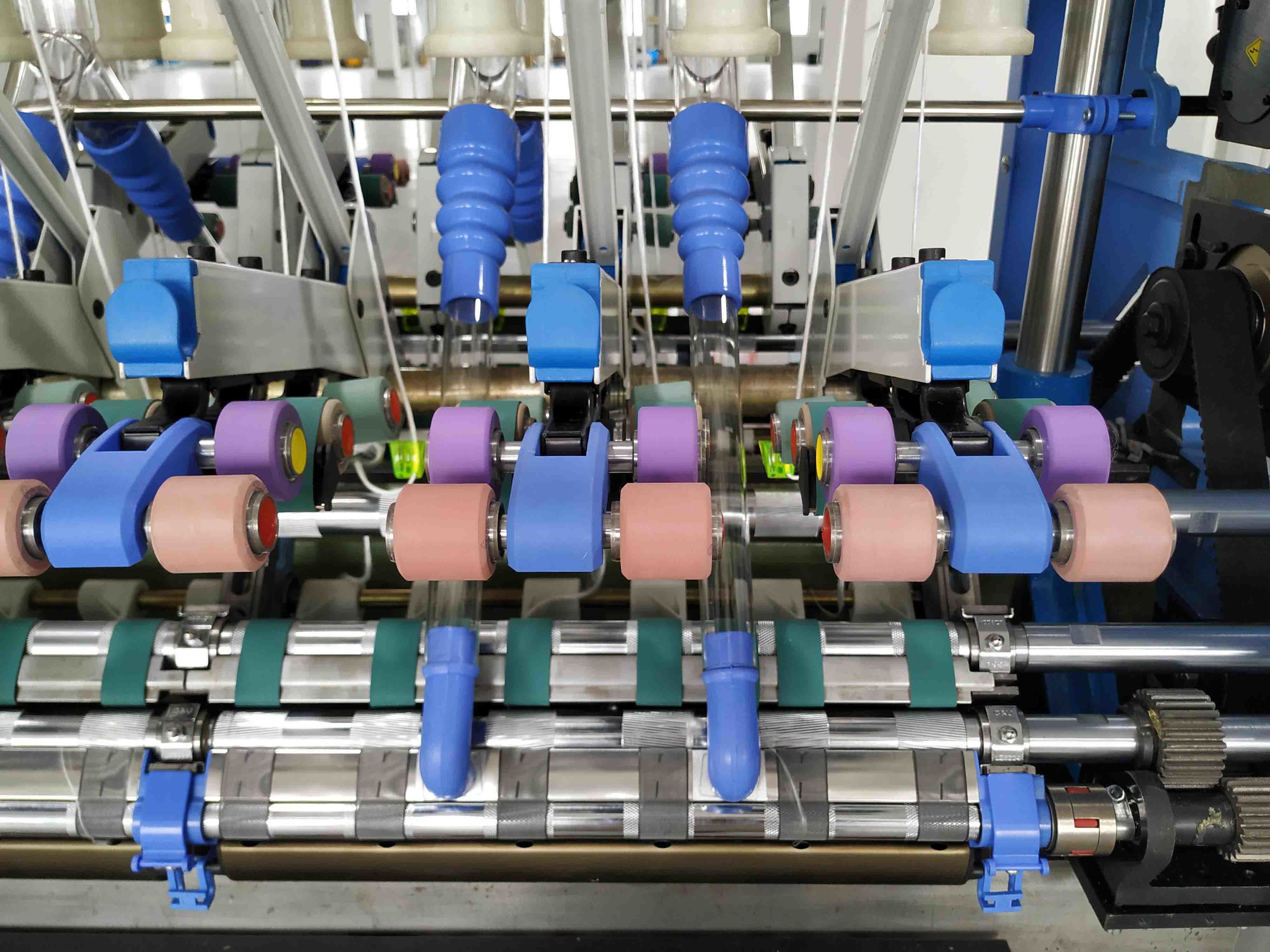

3 line rollers,double aprons(long and short),pendulum arm weighting |

|

Spindle |

Aluminum type or bare type with knee brake |

|

Roving Creel |

Φ128x320mm Bobbin hangers of four rows in single tier |

Optional

Four roller light pressurized compact spinning system

Adopting regular apron on ring frame machines' original cradle to achieve stable running and reach the requirement of compact spinning.

1.We adopt four roller compact spinning and Siro spun system to do remodelling on ring frames.Sound structure design, excellent spare part manufacture and remarkable yarn effect.

2.Yarn is more compact and has better finish. Yarn hairiness decreased obviously.Above 3mm of tube yarn, hairiness can be reduced more than 60%

3. Strength is increased by 10%-15%, compared with ring spinning.

4.CV% is better than ordinary yarn.

5.We can use a lower level of textile raw materials to produce the same quality of yarn as traditional ring spinning of spinning frame or use same raw materials to make out of higher quality yarn.

6.Breakage rate and fly decreased, hence the output increased obviously, the intensity of operative worker decreased significantly and the corporation cost declined.

|

|

|

|

Previous

Previous

RELATED PRODUCTS

INQUIRE