PRODUCT

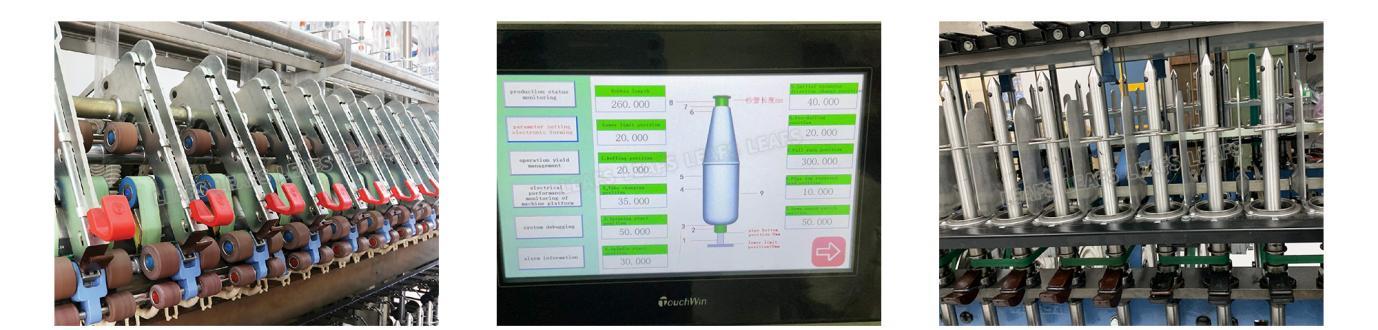

FB505 Woolen Ring Machine

Category:

Ring frame machine

Keyword:Yarn Spinning machine line

DETAILS

This machine is suitable for the pure spinning or mixed spinning of wool ,synthetic,blend,silk ,blend by which it feeds the thick yarns with or without twists to go through the procedures of stretching, twisting and rolling before becoming a single wool thread with a certain Nm.

The highest speed of spindle up to 13000 r/min, electrical control system adopts PLC control technology and AC servo control technology, which can make the equipment run steadily and reliably.

Specifications

|

Spindle Gauge |

75mm |

|

No.of spindles |

From 108 to 444 ( 12 spindles/section) |

|

Ring Diameter |

Φ48*11.2(semi-worsted spinning) |

|

Yarn Count |

8.3-50tex(20-120Nm) Normal supply 25-12.5Tex(40-80Nm) |

|

Twisting |

200-1260 (T/m)No limitation |

|

Spindle Speed |

Operating speed of empty spindle is up to 13000 (rpm) |

|

Spindle driving |

Double tape tension pulleys |

|

Draft Ratio |

Total draft:10-40 |

|

Twist Direction |

Z or S |

|

Draft System |

3 line rollers,double aprons (long and short),pendulum arm weighting with 6 spindles |

|

Compacting System |

4 line rollers,lattice apron with 6 spindles/section,double aprons(long and short) |

|

Spindle |

Aluminum type |

|

Roving Creel |

Φ200x200mm Double yarn without twist. |

|

Main Motor Power |

7.5KW(for 396 spindles) |

Features

1.Headstock Transmission

Spindle and headstock are driven by synchronous belt for avoiding noise. Twist, main drafting, wind change gear are designed with same modules, bore diameter and width, which can be in common use one another. In addition, headstock adopt fully closed oil bath headstock, tailstock adopt tooth face automatic oil drip the driving transmission is electronic driving.the front roller is driven by motor;middle and bottom roller is controled by frequenoy conversi on and PLC. this can ensure the synchronous accuracy.

2.Winding System

Spindle is the type of damping vibration absorption, which can be loaded with brake spindle device, adds balloon ring thread-guide plate, which is helpful to control the yarn's tension because of the separated movement of balloon lift and drop against ring plate. Excellent center accuracy between the ring to the spindle. Lift and drop movement structure of yarn guide plate, balloon ring and ring plate are balanced by heavy punch. In addition, rising and lowering of ring rail can adopt mechanical type or electric type.

3.Suction system

Every spinning frame has itinerated cleaning device, this can select suitable blowtorch components and blowpipe height according to spinning frame type, spinning frame type, spinning technology and requirement, spinning environment and characteristics of cleaning of device, it can effectively improve the yarn quality.

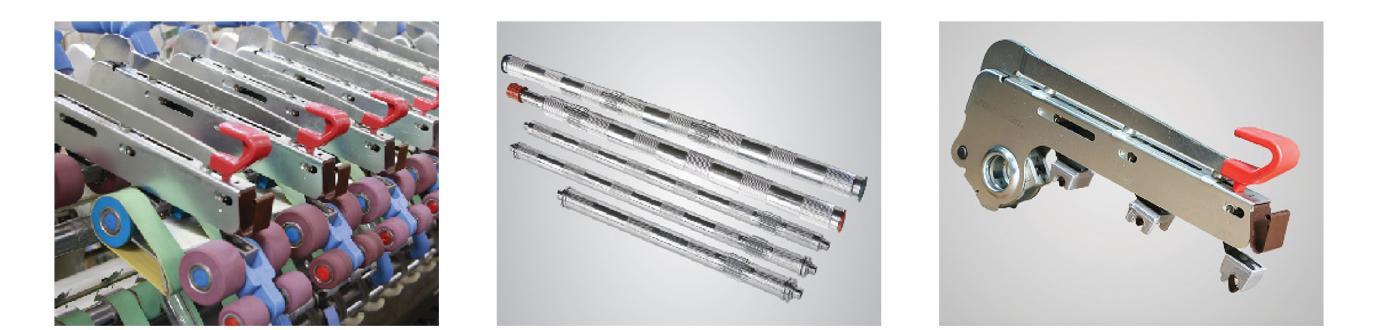

4.Draft Transmission

Adopts three rollers, double aprons drafting; compact spinning system adopts four rollers drafting with lattice aprons, adopt wool spinning leaf-spring pendulum arms.The broken yarn can be adsorbed into single branch pipe, the pipe is close to the bottom roller; with large suction entrance, the absorbing rate is higher for cleaning the surface of bottom roller.

5.Electric Control

All the electrical element of electrical system, such as programmable controller and transducer, all select and use world-famous brands and can realize synchronous control between electrical machines.Adopt colorized touch screen as instellective interface. Technological parameters can realize speedy,simple and optimized setting on screen, which is convenient for craft management.

6.Spindle Transmission

We adopt double tension pulley and single-motor transmission(four-spindle type),we can choose S-type or Z-type twisting type by changing the main motor turning direction. This can reduce the uneven rate of spindle speed,Adjust the speed by frequency conversion.

Details

|

Draft Transmission |

Electric Control |

Spindle Transmission |

|

Compact spinning(optional) |

Roller without mechanical wave |

Spring Pendulum Arm |

Previous

Previous

RELATED PRODUCTS

INQUIRE