PRODUCT

FB474 Roving frame machine

Category:

Roving frame machine

Keyword:Yarn Spinning machine line

DETAILS

FB474 Four axial computerized roving Frame machine, adopts the advanced microcomputer control technique.It uses 4 frequency converting motors to drive flyer,rollers,winding components and lift system components, and realizes precise proportional synchronizing action.The main drive system adopts circular arc toothed synchronous belt drive system.It is suitable for pure or blended processing of combed cotton fiber and artificial fiber.

Features

1.The twist value can be input directly on the function panel,so only drafting changeable gears required.

2.Sliver breakage protection system and constant tension spinning system.

3.Optimization of the design of the front drive and layout, the front layout is simple, good heat dissipation, easy to install and maintain. -Power off flyer auto-orientation,easy to operate.

4.The bridge shunt type wiring,electrical installation convenient reduce electrical signal interference.

5.With flyer intelligent variable speed programable spinning speed is greatly improved.

6.System a key to restore more energy,when the control system software parameters were broken ring, start a key to restore the initial state can be reduced to.

7.Network management can realize long-distance control.

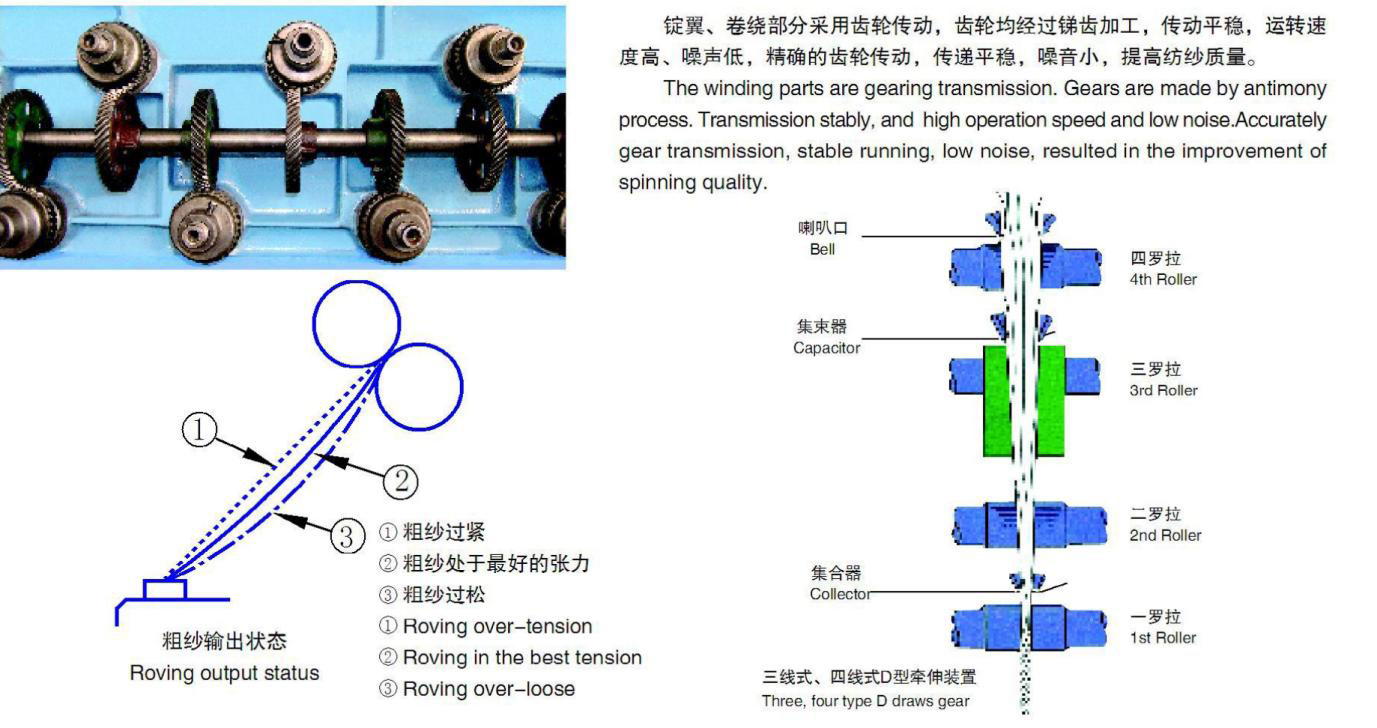

Gear transmission is adopted to drive flyer and bobbins,the running speed is more than 1600r/min,transmission smooth,lower noise,high efficiency.

Details

Specifications

Model | FA473 | FA474 |

Density For Roving Yan | 220-1250 tex | 220-1250 tex |

Length For Fibre (mm) | 22-65 | 22-65 |

Spindle Number (piece) | 24,36,48...... 120,144 | 24,26,48...... 120,144 |

Spindle Gauge (mm) | 220 | 194 |

Pitch Gauge (mm) | 440 | 388 |

Spindle number per pitch | 4 | 4 |

Drafting System | 4(3) Roller double* short-apron drafting | 4(3) Roller double* short-apron drafting |

Pressing Form | Pendulum Weighting Arm With Pneumatic Pressing | Pendulum Weighting Arm With Pneumatic Pressing |

Bottom Roller Diameter (mm) | φ28.5 φ28.5 | φ28.5 φ28.5 |

| φ28.5 φ28.5 | φ28.5 φ28.5 |

Top Roller Diameter (mm) | φ28.8 φ28.8 | φ28.8 φ28.8 |

| φ25 φ28.8 | φ25 φ28.8 |

Drafting Range | 4.4-13.3 | 4.4-13.3 |

Mechanical spindle speed | 1600 r/min | 1600 r/min |

Spindle process revolution | 1200 r/min | 1200 r/min |

Twist Range (twist/m) | 18.0-80 | 18.0-80 |

Bobbin Dimentions (mm) | Φ45*445 | Φ45*445 |

Take up package dimention | φ152x400 mm | φ135x400 mm |

Cleaning Device | Napping roller with revoiving suction device | Napping roller with revoiving suction device |

Transmission device | Four-shaft Linkage/4 servo motor | Four-shaft Linkage/4 servo motor |

Control Type | Computerized Model | Computerized Model |

Man-machine interaction | Touch Screen | Touch Screen |

Winding Roller Transmission | Gear transmission | Gear transmission |

Spindle roller transmission | Gear transmission | Gear transmission |

Winding Power Shaft | Universal shaft | Universal shaft |

Yam Forming Angle | Random | Random |

Three Automatic Doffing | Software | Software |

Signal Display | Five lamps indicated on machine headstock | Five lamps indicated on machine headstock |

Tension Adjustment | Software | Software |

Tension Fine Adjustment | Software | Software |

Preventing Pinched Yarn | Software | Software |

Sliver Faults preventing | Software | Software |

Previous

Previous

RELATED PRODUCTS

INQUIRE